Product Development

We are proud of our record in successfully transforming our customers’ visions from ideas to finished products. Our experienced team and impressive in-house resources make us the top choice for achieving this goal.

Communication is the key to successful product development. We will collaborate closely with you, advising on all aspects of the project, from design to the best development process to adopt.

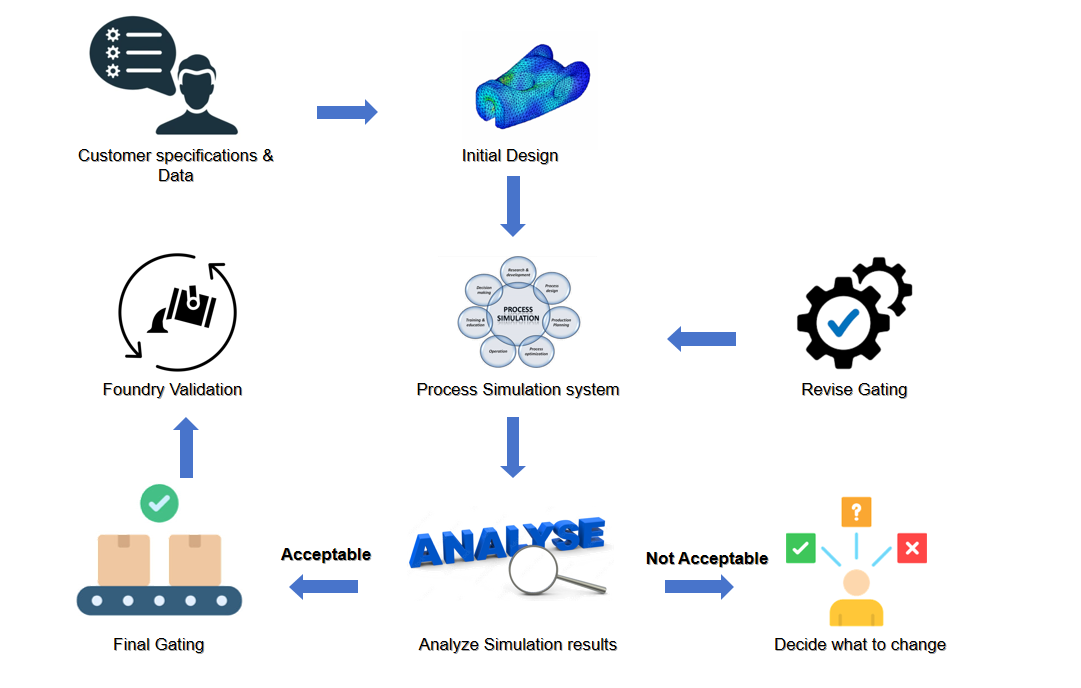

Below is a brief summary of our process:

Stage 1: Design for manufacture

Starting with a concept idea, an outline drawing, or a mock-up model, our design team can swiftly generate precise drawings that will assist you in finalizing your design needs.

The team collaborates with you to determine the important features needed for your project. We can modify your product to fulfill the task it was designed to do if we completely grasp your specifications.

Drawing/Model File Formats

To guarantee your product meets these specifications, we use

AutoCAD (.DWG)

.BMP

.DXF

.GIF

.IGES

.JPG OR .JPEG

SolidWorks

.STP OR .STEP

.TIF OR .TIFF

.STL

which allows you to visualize the finished product. Once satisfied, we can proceed to the simulation stage.

Stage 2: Initial Design

Once the designs have been accepted, we perform a comprehensive casting simulation with the purpose of generating optimum integrity to ensure that quality is maintained throughout the casting process.

CAD models or 3D are generated to simulate casting using software techniques that emulate the process. This eliminates the need for actual production testing and provides you and us with a high level of confidence before expensive tooling is built.

Stage 3: Develop

Once your product is designed and has undergone simulation, our technical team liaises with your design engineers to progress to development stage.